Crystalline

Feldkirch, Austria (2024)

From 9th to 12th October 2024, the "Spotlight" event in Feldkirch, Austria, organized by the Lichtstadt association, will showcase a cutting-edge light art installation titled "Crystalline". Created by Sofia Hagen, a multidisciplinary artist and architect originally from Vorarlberg and currently based in London, the installation is an intriguing fusion of art, design, and architecture. "Crystalline" features a 2.7 metres tall, illuminated salt crystal, prominently positioned in the historic centre of Feldkirch. This central piece is accompanied by smaller crystals, all of which are crafted from recycled medical plastic waste using advanced 3D printing technology. These sculptures are not only visually striking but also incorporate specifically designed light and sound elements that interact with the surrounding architecture, creating an immersive experience. The installation offers a unique blend of sustainable materials, innovative technology, and artistic expression that harmonizes with the historic context. The event is set to be a captivating experience, showcasing Sofia Hagen's talent in combining various artistic disciplines with a focus on environmental sustainability.

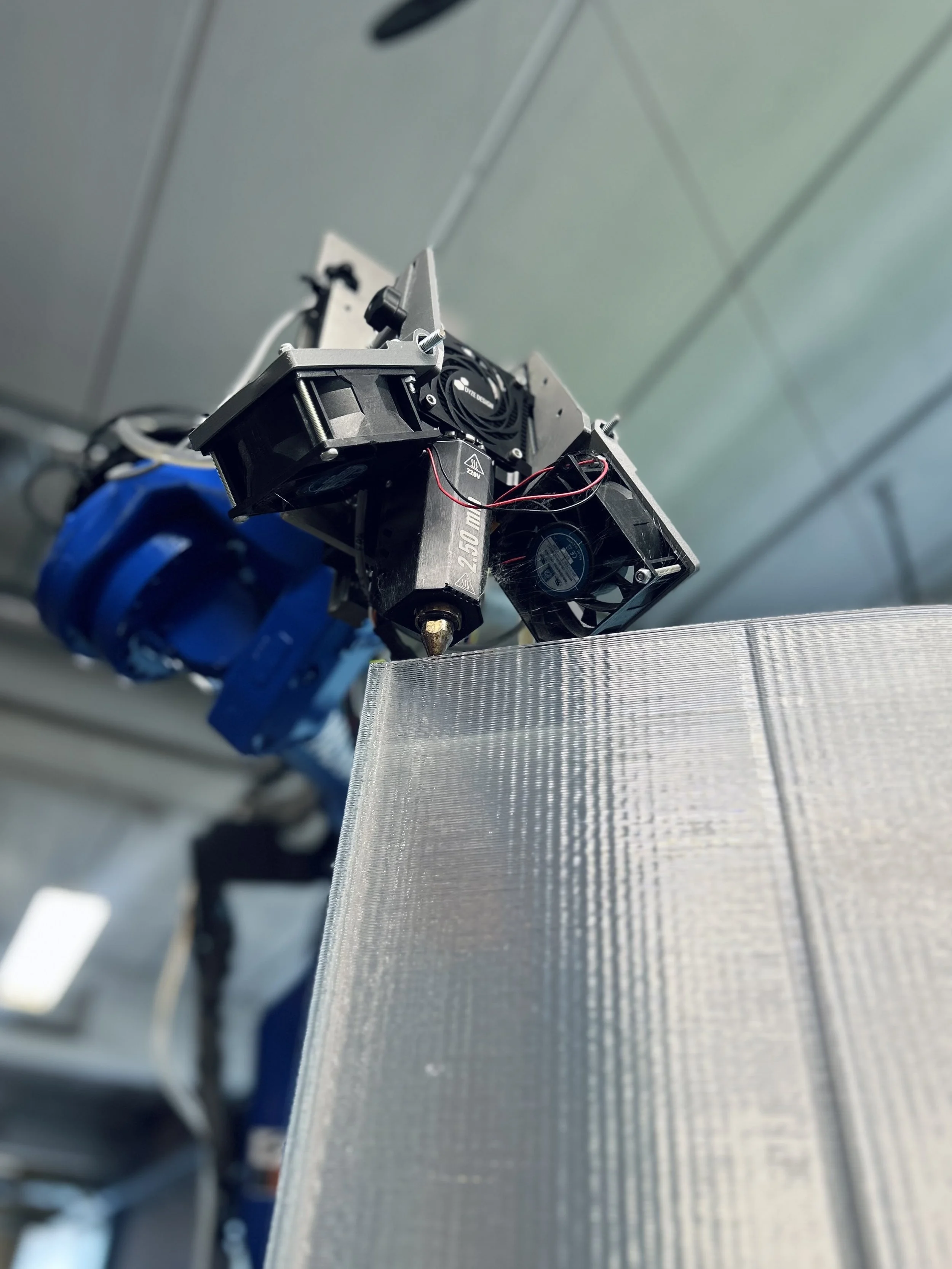

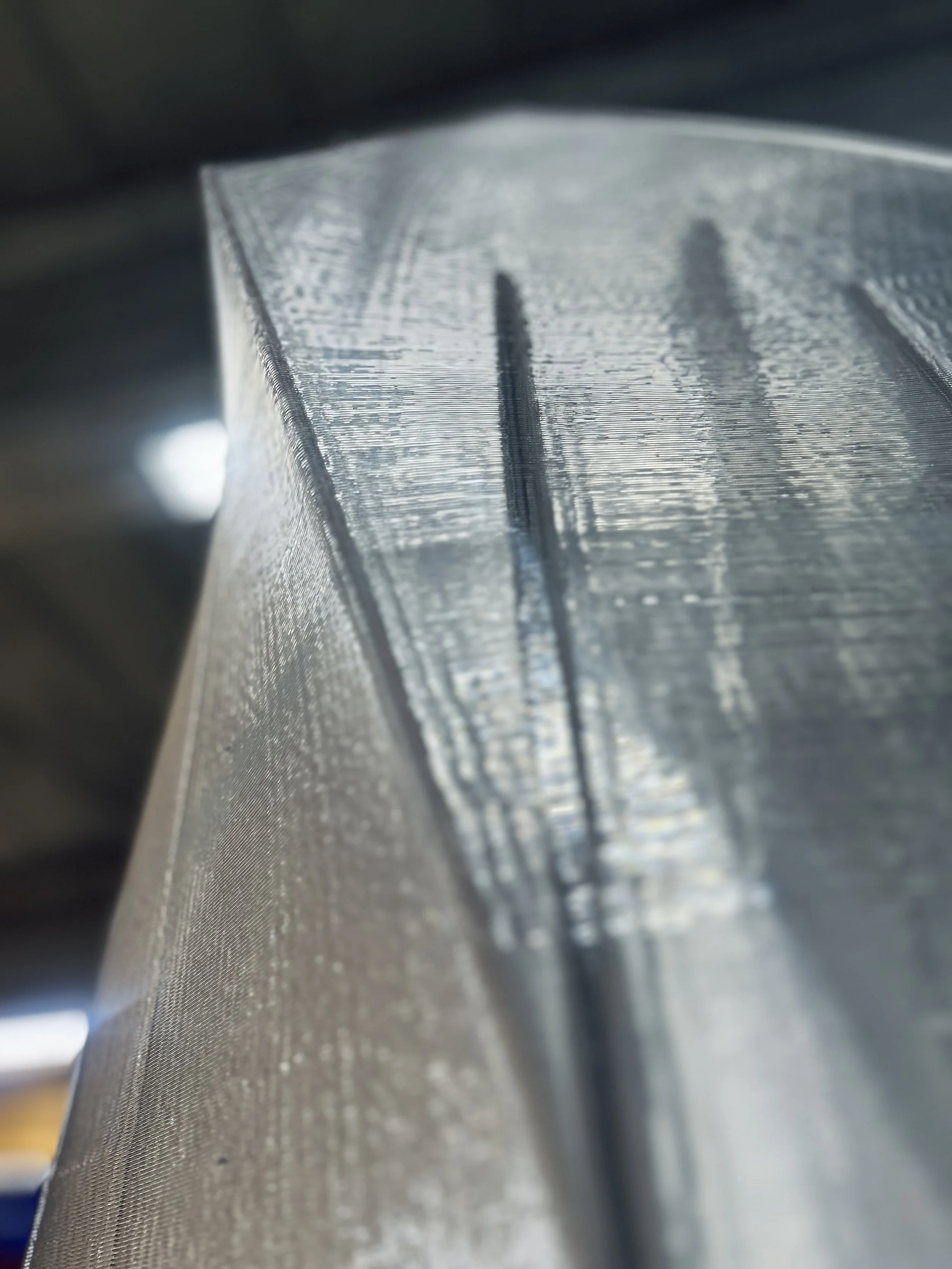

The manufacturer MDT A/S Flexible Products in Denmark produced the large crystal in a continuous 3D printing process lasting 68 hours. With a height of almost 3 metres it is the largest possible monolithic object that can be produced using this printing process. The material rPETG corresponds to recycled polyethylene terephthalate which has been modified with

glycol. The translucent filament was obtained from disposable containers from the medical sector and can only be reused for the production of 3D prints. As with crystal formation in nature, temperature and humidity play a role in the production of the filament and influence how the material behaves during printing and affect the translucency of the end result.

Define Engineers engineered the sculpture utilising state-of-the-art FEA analysis tools. The wind load for this temporary structure was worked out based on statistical data available for the area in order to avoid over-engineering of the components. Careful consideration of the material behaviour is necessary when working with 3D printed polymers and all strength verifications were carried out based on project specific material testing. Through careful balancing of the predicted external loads and the expected risks, our team pushed the limit of what is possible with rPET in external conditions, testament to which is the height of the sculpture.

Artist / Architect – Sofia Hagen

Structural engineering – Define Engineers

3D Print production – MDT, Denmark

Materials – Reflow, Netherlands

Light – Zumtobel, Austria

Photography credits – Guenter Richard Wett